What Is Wood Powder Activated Charcoal?

Wood powder activated carbon is made from high quality natural pine charcoal, which is processed by advanced equipment and scientific technology through the process of wood slice sorting, mixing and stirring with phosphoric acid, carbonization and high temperature activation, rinsing and so on. It is usually in the form of black fine powder, has strong adsorption capacity, can adsorb and remove organic pollutants, odors, pigments and other impurities from water or air.

Wood Powder Activated Charcoal Production Method

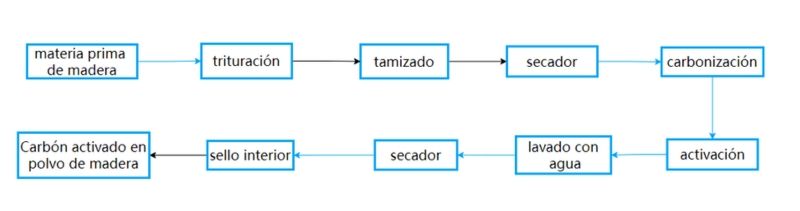

There are two methods of producing wood powder activated carbon: phosphoric acid production and zinc chloride production. In the production process, the raw material is crushed to a fine powder and then dried to reduce the moisture content. It is then carbonized and activated by physical or chemical methods.

Physical activation involves pyrolysis and shrinkage by hot air or auxiliary means such as steam to increase porosity and specific surface area; chemical activation involves the addition of alkaline activators such as phosphoric acid, alkaline potassium and zinc salts at carbonization temperature to oxidize and deliquesce the wood material and form a more porous structure. Post-treatment steps include washing, drying and screening to improve the adsorption performance and stability of the activated carbon.

Advantages Of Wood Dust Activated Charcoal

Wood powder activated carbon, as a highly efficient and multifunctional adsorbent, plays a key role in many fields thanks to its excellent performance. Here are some of its main advantages:

- High purity and low impuritiesWood-based powdered activated carbon is typically of high purity and low impurities, making it useful in applications where high purity adsorbents are required.

- Developed pore structureWood powdered activated carbon has a highly developed pore structure, which gives it a large specific surface area, thus improving its adsorption capacity.

- High adsorption capacityWPC: thanks to its high specific surface area and porous nature, WPC is capable of adsorbing a wide variety of organic and inorganic substances, including pigments, odors and noxious substances.

- Fast filtration speedThe powder form of wood powder activated carbon makes it have faster filtration speed in the filtration process, which is suitable for the occasions that need quick treatment.

- Good bleaching effectIn the pharmaceutical and food industries, wood powder activated carbon is often used in the decolorization process, which can remove the pigment in the products and improve the appearance of the products.

- Deodorization and removal of impuritiesWood powdered activated carbon can effectively remove odors and impurities, and improve the taste and odor of products.

What Is Activated Wood Charcoal Powder Used For?

Wood powder activated carbon has the characteristics of lower impurity, high purity, fast filtration speed, etc. It has excellent performance of decolorization, purification, purification, etc. It is mainly used in decolorization, refining and removal of heat source of all kinds of injectable pharmaceuticals.

It can also be used for decolorization of vitamin C and other raw materials, with strong decolorizing power, fast filtration speed, suitable for decolorization and refining of pharmaceutical industry. Can be used for absorbing intestinal bacteria, detoxification, sugar, monosodium glutamate (MSG), food and beverage, water treatment, chemical industry, etc. It can be used for decolorizing, deodorizing, removing impurities, purifying and refining.