Activated carbon is a versatile and effective material with a wide range of industrial and environmental applications. Among the many types of activated carbon, bituminous activated carbon stands out for its unique properties and excellent performance.

In this article, we will take an in-depth look at the definition of bituminous activated carbon, its production process, its unique properties and the applications that make it an integral part of many industrial processes.

What Is Bituminous Activated Carbon?

Bituminous Activated Carbon is a specific type of activated carbon produced from bituminous coal. Bituminous coal is a medium quality fossil coal, known for its high energy content and versatility in various industrial applications.

This type of activated carbon is characterized by its highly developed pore structure, which gives it a large internal surface area and excellent adsorption capacity.

Compared to other types of activated carbon (such as coconut shell activated carbon or the wood-based activated carbon), el Carbón Activo Bituminoso suele presentar una distribución de poros más diversa, lo que lo hace particularmente eficaz en una amplia gama de aplicaciones.

Bituminous Activated Bituminous Coal Production Process

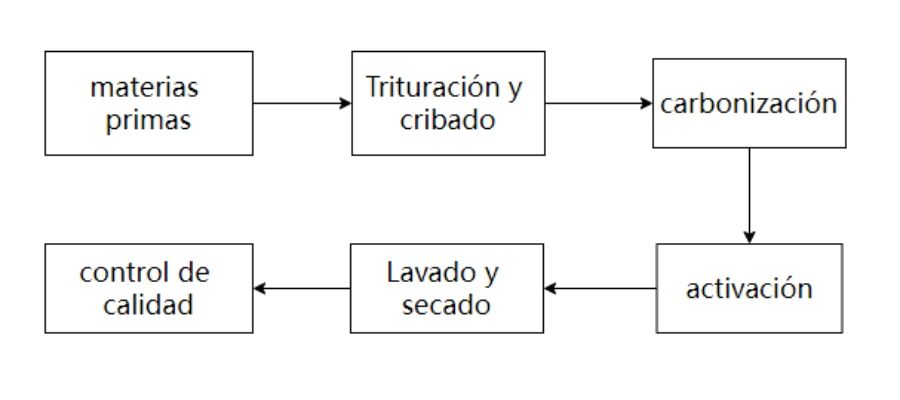

The production of Bituminous Activated Carbon involves several carefully controlled steps:

- Raw material selectionHigh quality bituminous coal is selected as the base material.

- Crushing and screeningThe coal is crushed and screened to obtain the desired particle size.

- CarbonizationThe material is heated in an oxygen-free environment at high temperatures (400-800°C) to remove the volatile components.

- ActivationPhysical activation: This step can be performed by two methods. Physical activation is carried out at high temperatures (800-1000°C) using gases such as water vapor or CO2. Chemical activation uses chemical agents such as phosphoric acid or zinc chloride.

- Washing and dryingThe activated carbon is washed to remove impurities and then dried.

- Quality controlTests are performed to ensure that the activated carbon meets the required specifications.

At PuroCarbon S.L., we pride ourselves in using advanced technology in our production process to ensure that our Bituminous Activated Carbon reaches the highest quality.

Properties and Advantages of Bituminous Activated Bituminous Coal

Bituminous activated carbon has a number of unique characteristics:

- High adsorption capacityIts developed porous structure provides a large internal surface area for adsorption of contaminants.

- Hardness and abrasion resistanceHarder and more durable than other types of activated carbon, making it suitable for applications requiring multiple cycles of use.

- Wide pore distributionThis allows it to adsorb both small and large molecules efficiently.

- Good reactivation capacityCan be reactivated and reused several times, which makes it economically advantageous in the long term.

- VersatilityIt is effective in a wide range of applications, from water treatment to air purification and solvent recovery.

Bituminous Activated Carbon Applications

Bituminous activated carbon is used in several fields:

- Water treatmentEffectively removes organic contaminants, chlorine, bad odors and tastes from drinking water and wastewater.

- Air purificationUsed in ventilation systems to eliminate toxic gases, odors and volatile organic compounds.

- Solvent recoveryIt is used in industrial processes to recover and reuse valuable solvents.

- Industrial gas treatmentEffectively removes pollutants from industrial exhaust gases.

Comparison With Other Activated Carbon Types

While Bituminous Activated Carbon shares many characteristics with other types of activated carbon (such as coconut shell activated carbon or wood-based activated carbon), it excels in several respects:

- Increased hardness and abrasion resistanceThis makes it more durable in applications requiring multiple use cycles or fast flow conditions.

- More diverse pore distributionThis allows it to be effective in a wider range of applications.

- Increased adsorption capacity for certain pollutantsIt is particularly effective in adsorbing larger organic molecules.

- Improved reactivation capacityCan be reactivated and reused more times than some other types of activated carbon.

However, it is important to note that each type of activated carbon has its own advantages, and the choice depends on the specific application.

Request a QuoteConclusion

Bituminous activated carbon is widely used in various industries due to its highly developed porous structure and exceptional durability. At PuroCarbon S.L., we offer high quality Bituminous Activated Bituminous Carbon.

If you are looking to improve your purification processes or to explore the possibilities of bituminous activated carbon, do not hesitate to contact us at. Our team of experts will be pleased to advise you and provide you with detailed information about our products.

Frequently Asked Questions

La principal diferencia radica en la materia prima y la estructura porosa resultante. El Carbón Activo Bituminoso tiende a tener una distribución de poros más diversa y una mayor dureza, lo que lo hace más versátil y duradero en muchas aplicaciones.

Cost can vary depending on the specific application and quality required. While the initial cost may be higher than some other types, its durability and reactivation capability may make it more economical in the long run.

Sí, una de las principales ventajas del Carbón Activo Bituminoso es su excelente capacidad de regeneración. Puede reactivarse y reutilizarse varias veces, lo que lo hace económicamente beneficioso en muchas aplicaciones industriales.

Muchos grados del carbón activo bituminoso están certificados para su uso en el tratamiento de agua potable y en aplicaciones de procesamiento de alimentos. Sin embargo, es crucial verificar las certificaciones y la idoneidad para cada aplicación específica.

La elección del carbón activado adecuado implica considerar factores como el tipo de contaminantes a eliminar, las condiciones del proceso, los requisitos reglamentarios y las restricciones económicas. En PuroCarbon S.L., ofrecemos asesoramiento experto para ayudar a los clientes a seleccionar el producto más adecuado para sus necesidades específicas.