Activated carbon is a highly adsorbent material manufactured from carbon source material through a series of complex physical and chemical treatment processes. Activated carbon production is a sophisticated and complex process that requires professional expertise and advanced technology. Different types of activated carbon have their own unique production processes due to differences in raw materials and applications. In the following, we will introduce the production process of the three main types of activated carbon, namely granular activated carbon, pellet activated carbon and wood activated carbon, to demonstrate our experience and craftsmanship in the field of activated carbon manufacturing.

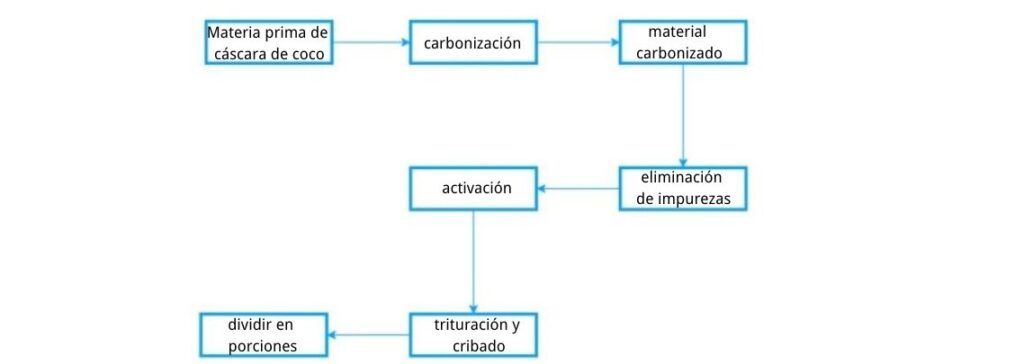

Granular Activated Carbon Production Process

Here is an example of coconut shells, which are brought to the factory, crushed into pieces of the appropriate size and washed to remove surface impurities. The cleaned coconut shell pieces are then dried to ensure that the moisture content is less than 10%. The dried coconut shell pieces are placed in a carbonization oven and heated to over 600°C to carbonize them. After carbonization, it is removed and cooled to room temperature, then sieved to remove defective products and impurities. Finally, the standardized coconut shell charcoal is packaged.

The process flow diagram is shown below:

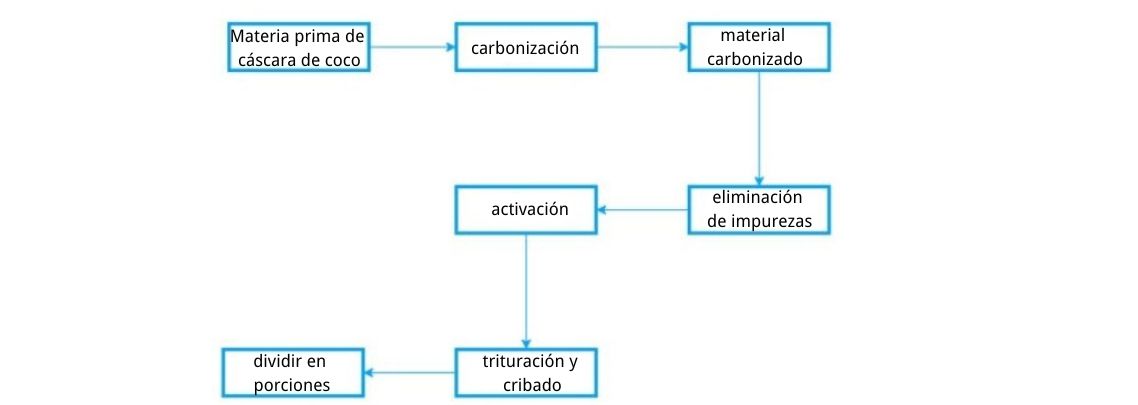

Activated Charcoal Pellet Production Process

After entering the plant, the qualified raw material coal, with anthracite coal as the main raw material, is crushed to a certain fineness (usually 200 mesh), and then an appropriate amount of binder (usually coal tar) is added and mixed well in the mixing and kneading equipment; and then it is extruded into charcoal briquettes with molds of certain diameters under a certain pressure. After carbonization and activation, the charcoal briquettes are sieved and packed into finished activated carbon.

The process flow diagram is shown below:

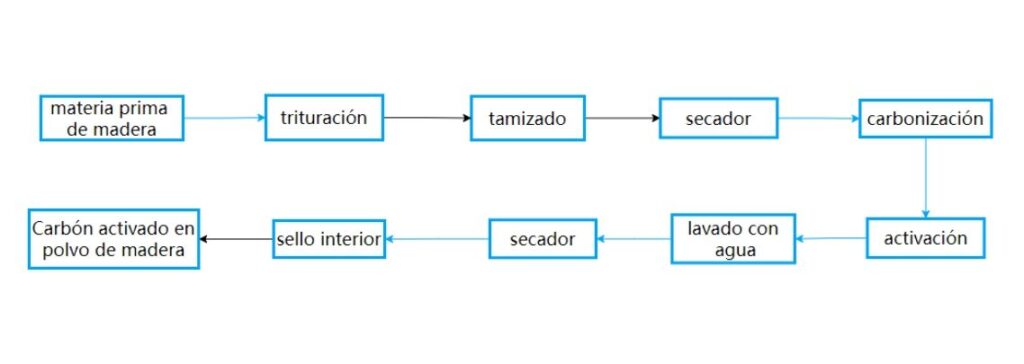

Wood Activated Charcoal Production Process

High-grade wood is ground to a fine powder, dried to reduce moisture content, mixed with phosphoric acid and other chemical agents, then carbonized and activated under high-temperature conditions in a rotary kiln to form activated carbon products with high adsorption properties. The product is then rinsed, screened and tested to ensure that the product quality meets the standard.

The process flow diagram is shown below:

Request for Quotation

Are you looking for a high quality and reasonably priced activated carbon product solution? Don't hesitate any longer! Contact us now for a customized quote.