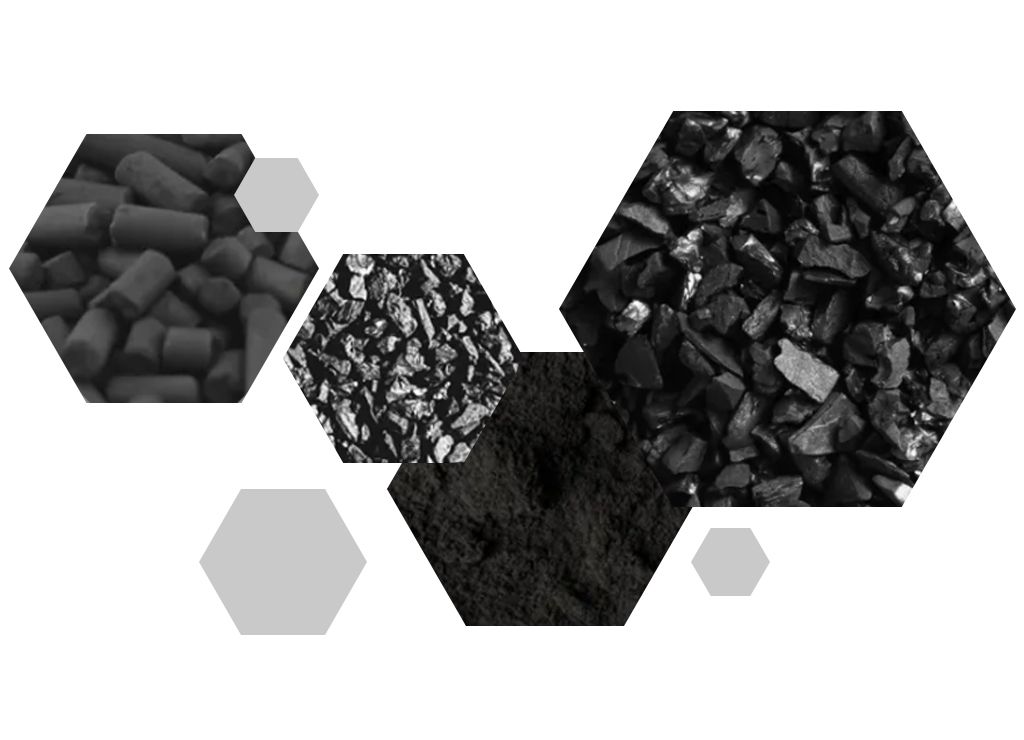

Complete Product Portfolio

We offer the most complete line of activated carbon products. Whether you need to treat gases, liquids or specialized applications, we have the most suitable products to meet the diverse needs of all industries.

With advanced R&D capabilities and strict quality control, we not only provide high quality activated carbon products, but also professional technical assistance and customized services to ensure that each customer's needs are met.

Production experience

annual production capacity

Export markets

Cooperating customers

PUROCARBON offers a complete range of activated carbon solutions. We offer a wide range of activated carbon, from granular to powder, from alveolar to pellet, to meet the diversified needs of various industries.

We offer the most complete line of activated carbon products. Whether you need to treat gases, liquids or specialized applications, we have the most suitable products to meet the diverse needs of all industries.

We have implemented a complete quality control process, from the purchase of raw materials to the finished product, every link is strictly controlled. We ensure that each batch of products meets or exceeds industry standards, providing customers with reliable quality assurance.

We are able to efficiently manage shipping needs on a global scale. Whether by air, sea or land, we are able to select the optimal logistics solution based on our customers' needs, ensuring that our products reach every corner of the globe safely and quickly.

We have established a complete supply chain management system and maintained long-term stable relationships with various raw material suppliers. Thanks to scientific inventory management and production planning, we can guarantee a continuous and stable supply of products.

Thanks to large-scale production and effective cost control, we offer competitive prices to our customers. Depending on the purchasing volume and the depth of cooperation of our customers, we establish a flexible pricing policy, so that you can enjoy high quality products and get more favorable.

We offer 24-hour customer support so we can respond quickly wherever you are and whenever you need help. Through multiple channels such as phone, email and online chat, our professional customer service team is always on standby to provide you with quick solutions.

Are you looking for a high quality and reasonably priced activated carbon product solution? Don't hesitate any longer! Contact us now for a customized quote.