What Are VOCs and What Are Their Hazards?

VOC is a general term for volatile organic compounds, including alkanes, olefins, alkynes, benzenes, alcohols, aldehydes, ethers, ketones, acids, esters, halogenated hydrocarbons, etcetera.

They come mainly from fuel combustion and industrial emissions from transportation, vehicle exhaust, photochemical pollution, etc. outdoors; while indoors, they come mainly from combustion products such as coal and natural gas burning, smoke from smoking, heating and cooking, etc., and from emissions from construction and decoration materials, furniture, household appliances, production of automotive interior parts, cleaning products and the human body itself.

VOCs have a huge impact on human health. When VOCs in the living room reach a certain concentration, for a short period of time, people will feel headache, nausea, vomiting, fatigue, etc., and in severe cases, they will have convulsions and coma, and damage people's liver, kidneys, brain and nervous system, leading to memory loss and other serious consequences.

In addition, VOCs are also an important precursor to the formation of secondary pollutants such as fine particulate matter (PM2.5) and ozone (O3), which in turn cause atmospheric environmental problems such as haze and photochemical smog.

Advantages of Activated Carbon for VOC Gas Removal

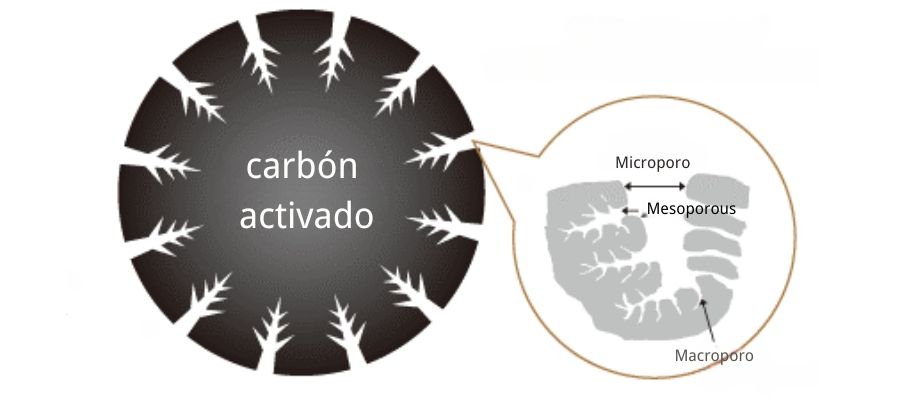

Activated carbon is a kind of adsorption material with a highly developed porous structure, and its unique physicochemical properties determine its outstanding advantages in VOC gas removal. Firstly, activated carbon has a large specific surface area of 500-2000 square meters per gram, which provides a large number of active sites for adsorption of VOC gases.

Secondly, the porous structure of activated carbon can effectively capture VOC molecules and prevent them from entering human respiratory system. At the same time, the activated carbon has good chemical stability and adsorption regeneration ability, and can work effectively for a long time.

How To Choose The Right Activated Carbon For Cov Removal?

To take full advantage of the benefits of activated carbon in the removal of VOC gases, it is important to choose the right activated carbon product. We recommend users to pay attention to the following aspects:

Specific Surface

The specific surface area is the key index for determining the adsorption performance of activated carbon. Generally speaking, the larger the specific surface area, the higher the adsorption performance. The ideal activated carbon product should have a specific surface area of 800-1500 square meters per gram, which can provide a large number of adsorption sites for VOC molecules.

Pore Size Distribution

The pores of activated carbon include micropores, mesopores and macropores, and the three pore sizes play different roles in VOC adsorption. Micropores provide adsorption sites with a large specific surface area, mesopores provide channels for diffusion and migration of VOC molecules, and macropores facilitate the entry and exit of VOC molecules. Therefore, it is important to select activated carbons with a reasonable ratio of pore sizes to ensure effective adsorption of VOC molecules.

Chemical Properties

In addition to the physical structure, the chemical properties of activated carbon also affect its VOC adsorption performance. The ideal activated carbon should have good chemical stability, be able to resist acid and alkaline corrosion, and also have strong adsorption regeneration ability to ensure long-term efficient work.

Activated Carbon For Cov Removal

Choosing the right activated carbon to remove VOC gases is essential to ensure effective air purification. Granular activated carbon and column activated carbon are typically used for VOC removal.

Granulated Activated Carbon

The granular activated carbon is made from high quality bituminous coal, refined by crushing, screening, activation and other processes, with developed pore structure, high specific surface area and excellent mechanical strength, can effectively remove VOCs. common parameters are as follows:

| Indicator | Parameter |

|---|---|

| Iodine value | 800-1200 mg/g |

| CTC | ≥60% |

| Size | 4-8 meshes, 4-12 meshes |

| Hardness | ≥95% |

Activated Charcoal Pellet

The pelletized activated carbon is cylindrical in shape and is manufactured by a specific carbonization and activation process. It is known for its excellent mechanical strength, well-developed pore structure and highly efficient adsorption capacity for effective removal of vocal gases with the following parameters:

| Indicator | Parameter |

|---|---|

| Iodine value | 800-1200 mg/g |

| CTC | ≥60% |

| Specific surface | 800-1200 m²/g |

| Ash content | ≤10% |

| Hardness | ≥95% |

| Size | 3mm、4 mm |