El carbón activado es reconocido por su excelente capacidad de adsorción, desempeñando un papel insustituible en diversos campos como el medio ambiente, la medicina, la industria química y el procesamiento de alimentos. Entre los numerosos productos de carbón activado, el carbón activado granular, el carbón activado en pellet y el carbón activado en polvo se destacan como las tres opciones principales en el mercado debido a sus formas y características de rendimiento únicas.

Although these three types of activated carbon possess high adsorption capacity, there are significant differences in terms of shape, particle size, specific surface area, pore structure and application areas. This article will perform a comprehensive comparative analysis of these three types of activated carbon, exploring their differences to help you make a more informed decision.

What Is Granular Activated Carbon?

The granular activated carbon is a high purity carbon material, known for its large surface area and porous structure, which makes it extremely effective in liquid and gas phase purification applications. The particle size of granular activated carbon generally ranges from 0.2 millimeters to 5 millimeters, allowing it to perform optimally in a variety of filtration and adsorption processes. The particle size, or "mesh", is selected according to the specific needs of the application.

Production Method

The production method of granular activated carbon includes mainly two stages: carbonization and activation. Carbonization involves pyrolysis of the material at high temperatures to remove moisture and volatile substances, generating carbon. Activation consists of oxidizing the carbon using gas or steam at high temperature to increase its porous structure and specific surface area.

- CarbonizationCarbonization is generally carried out in an environment with little or no oxygen, where the material is heated to a certain temperature to decompose into carbon and volatile substances.

- ActivationThe activation process generally uses steam or chemical activation methods to form a large number of micropores and mesopores on the carbon surface, increasing its specific surface area and adsorption capacity.

Raw Materials and Common Sizes

Granular activated carbon can be produced from a wide variety of raw materials, such as coal (hard coal, anthracite, lignite), wood, fruit shells and coconut shells. Different raw materials affect the performance of activated carbon; for example, coal-based activated carbon has higher strength, while coconut shell-based activated carbon has a higher specific surface area.

El tamaño del carbón activado granular se mide en mallas, y los tamaños comunes incluyen 4-8 mallas, 6-12 mallas,8-30 mallas, 40-60mallas, etc. Diferentes aplicaciones requieren diferentes tamaños de carbón activado. Por ejemplo, en la gold miningactivated carbon of 6-12 mesh is commonly used.

Main Application Areas

Granular activated carbon has a wide range of applications in many fields, playing a crucial role in improving the quality of life, protecting the environment and promoting health. The main areas of application include:

- Water treatmentRemoval of organic pollutants, odors and pigments from water.

- Air purificationAdsorption of industrial waste gases and harmful substances in indoor air.

- Food processingDeodorization, decolorization and purification.

- Pharmaceutical industryPurification of drugs and adsorption of toxins.

- Metal recoveryPrecious metals recovery and purification.

- Catalytic applicationsAs a catalyst or catalyst support, widely used in chemical reactions.

What Is Activated Charcoal Pellet?

The pelletized activated carbon is a form of activated carbon that generally comes in small cylindrical particles, with a diameter ranging from 3 millimeters to 5 millimeters.

This type of activated carbon is produced by a physical or chemical activation process, and is characterized by a highly developed pore structure and a large specific surface area, which makes it very effective in adsorption applications, especially in fixed bed adsorption systems, where it can provide efficient adsorption and desorption operations.

Production Method

The manufacturing process of pellet activated carbon is similar to that of granular activated carbon, also including the carbonization and activation stages. However, due to its regular shape, special treatment is required during activation to ensure its shape and strength.

- MoldingThe pellet activated carbon molding process generally uses extrusion or pressing methods, where the powdered activated carbon material is pressed into regular cylindrical particles.

- ActivationThe activation process generally uses steam or chemical activation methods to form a large number of micropores and mesopores on the surface of the carbon, thus increasing its specific surface area and adsorption capacity.

Raw Materials and Common Sizes

The pelletized activated carbon can be manufactured from a variety of carbonaceous materials. The choice of material has a significant influence on the performance and efficiency of the activated carbon, so it is important to understand the different materials available.

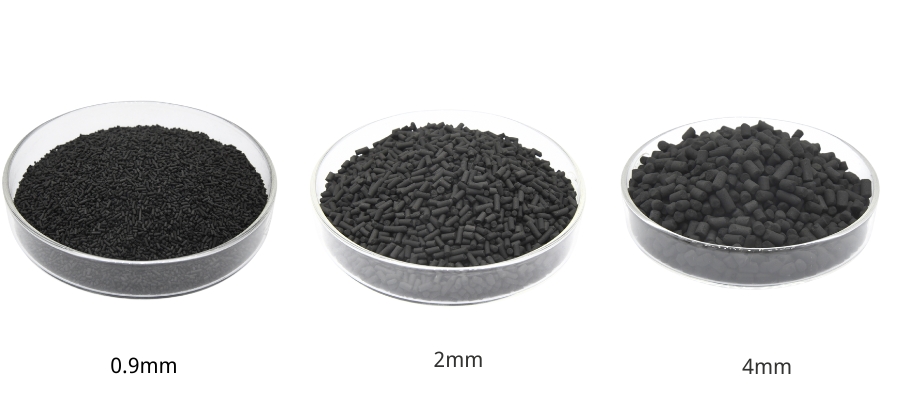

Pelleted activated carbon is commonly produced from coconut shells, fruit shells, wood or charcoal, which undergo carbonization and activation processes. Common sizes include 0.9mm, 1mm, 1.5mm, 2mm, 3mm, 4mm, etc.

The choice of the specific size generally depends on the application requirements, such as fluid flow rate, adsorption efficiency and equipment design needs. We also offer various types of impregnated carbonThe company has a wide range of products, such as potassium hydroxide (KOH) impregnation and copper oxide (CuO) impregnation, to meet the diverse needs of customers.

Main Application Areas

Pellet activated carbon is valued in many industrial and environmental engineering applications due to its physical form and performance characteristics. It provides an effective adsorption solution, especially suitable for fixed bed adsorption systems, and is commonly used in the following areas:

- Waste gas treatmentAdsorption and removal of noxious gases, such as hydrogen sulfide and nitrogen oxides.

- Water treatmentRemoval of organic pollutants, chlorine and heavy metals from water.

- Desulfurization and denitrificationIn the environmental industry, it is used for the treatment of desulfurized and denitrified gases, helping to reduce atmospheric pollution.

- Solvent recoveryCan adsorb organic solvent vapors, such as benzene and ether, allowing their recovery and reuse.

- PharmaceuticalsUsed for adsorption, detoxification and decolorization of drugs.

- Gas separationSeparation and purification of gaseous components.

What Is Activated Charcoal Powder?

The powdered activated carbon is a fine activated carbon with a particle size of less than 0.18 mm, and is usually in the form of a black powder. Powdered activated carbon has a larger external surface area, which allows it to offer a faster adsorption rate in a short period of time. However, due to its small particle size, powdered activated carbon tends to form suspensions during use, requiring additional separation steps.

Production Method

The production method of powdered activated carbon is mainly divided into two categories: physical and chemical. The physical method uses high quality fruit peels or sawdust which, after steam activation, are refined and pulverized to obtain activated carbon with high specific surface area and adsorption capacity.

The chemical method involves the selection and drying of sawdust, mixing it with a chemical activating agent (such as zinc chloride), followed by carbonization and activation in an activation furnace. After activation, the charcoal is washed, dewatered, dried and ground to obtain the final product of powdered activated carbon.

Raw Materials and Common Sizes

Powdered activated carbon is a porous, high surface area carbon material, usually made from organic materials such as wood, coconut shell or charcoal.

These materials, after a specific activation process, form a network of pores and fissures within the carbon structure, which gives the activated carbon a high adsorption capacity. Common sizes include 100/200/325 mesh, such as in the wastewater treatment where we commonly use 200 mesh activated carbon.

Main Application Areas

Due to its high surface area, powdered activated carbon has a very strong adsorption capacity, being able to rapidly adsorb organic pollutants, pigments, odors, etc., in water, with wide applications.

- Water treatmentUsed for emergency treatment or municipal water treatment.

- Wastewater treatment: Elimination of organic compounds difficult to degrade and heavy metals.

- Food industryUsed for the decolorization and purification of liquid foods.

- Pharmaceutical industry: Drug refining and pigment removal.

- Incineration gas treatmentAble to effectively adsorb and remove harmful substances such as sulfur, dioxins and mercury in incineration gases.

- Soil improvementUsed to improve soil properties by reducing the content of heavy metals and organic compounds in the soil.

Main Differences Between Granular, Pellet and Powdered Activated Carbon

Among the different types of activated carbon, granular activated carbon, pellet activated carbon and powdered activated carbon are often compared. Although all three have high adsorption performance, there are significant differences which are detailed below:

Particle Size and Specific Surface Areas

Granular activated carbon has a larger particle size, moderate specific surface area and a well-developed pore structure, making it suitable for use in fixed beds.

Pellet activated carbon has a uniform particle size and regular shape; its specific surface area may be slightly smaller than that of granular activated carbon, but its pore structure is still good, making it suitable for gas-phase adsorption and purification of industrial gases.

Powdered activated carbon has the smallest particle size and the largest specific surface area, providing the most adsorption points and the highest adsorption capacity, but it is prone to sedimentation in liquids, so attention should be paid to its dispersion during use.

Adsorption Capacity

Granular activated carbon has a moderate adsorption capacity, suitable for treating larger particle size contaminants. Pellet activated carbon, due to its structure, generally has a high adsorption efficiency. Powdered activated carbon, with its high surface area, can rapidly adsorb large amounts of contaminants, but its use often requires frequent replacements.

Regeneration Capacity

Granular activated carbon has a high regeneration capacity, suitable for multiple uses. Pellet activated carbon has a good regeneration capacity, although its useful life can be affected by structural damage. Powdered activated carbon has a relatively low regeneration capacity, generally being discarded after use.

Useful Life

Granular activated carbon has the longest service life, suitable for long-term applications. Pellet activated carbon has the shortest service life, significantly influenced by flow rate and conditions of use. Powdered activated carbon has the shortest service life, requiring frequent replacements.

Cost Factors

Granular activated carbon has a moderate cost and is suitable for large-scale applications. Pellet activated carbon has a relatively higher cost, but its high efficiency makes it suitable for high throughput demands.

Powdered activated carbon has a lower cost, but the long-term cost may increase. Therefore, the choice of one type or another of activated carbon should be based on the specific needs of the application, budget and treatment objectives.

Based on the differences between the three types of activated carbon, I have summarized the following table:

| Features | Granular Activated Carbon | Activated Charcoal Pellet | Powdered Activated Carbon |

|---|---|---|---|

| Surface area specific | Media | Download | High |

| Mechanical resistance | High | High | Download |

| Regeneration capacity | Fort | Good | Weak |

| Shelf life | Long | Cut | Very short |

| Cost-benefit | Medium | Medium | Under |

Activated Carbon Selection

The choice of the right activated carbon depends on your specific needs. If you need to treat liquids, such as drinking water or in food processing, the right activated carbon can be used. powdered activated carbon may be the best option.

If you need to treat gases, such as industrial waste gas or vehicle emissions, the pelletized activated carbon may be more suitable. If you need to treat solids, such as contaminants in soil or water bodies, the granulated activated carbonr can be more effective.

When selecting activated carbon, it is also necessary to consider the cost-benefit ratio. Powdered activated carbon is usually less expensive than granular activated carbon and pellet activated carbon, but its regeneration cost is higher.

Request a QuotePurocarbon is a specialized supplier in the production, research and sale of activated carbon, with more than 18 years of experience in the activated carbon market. In addition, we have a professional technical team. If you would like to purchase activated carbon or seek technical assistance, please do not hesitate to contact us.