Mercury is a toxic metallic element that is widely found in nature and is generated in industrial processes. Mercury compounds represent a great danger to the environment and human health, especially due to air and water pollution.

Therefore, mercury removal has become a key task in many industrial and environmental fields. In this regard, activated carbon, due to its excellent adsorption properties, has become an effective material for mercury removal. This article will focus on the application of activated carbon in the removal of mercury from flue gas and liquefied natural gas.

Principle of Mercury Removal with Active Carbon

The principle of mercury removal with activated carbon is mainly based on its exceptional physical and chemical adsorption characteristics.

Activated carbon has a high specific surface area and a developed porous structure, which allows it to offer a large number of adsorption sites that help capture mercury molecules in gaseous or liquid state. Adsorption of mercury on the surface of activated carbon can take place through two mechanisms: physical and chemical adsorption.

Physical adsorption

Physical adsorption occurs through Van der Waals forces and other weak interactions, which allow mercury molecules to adhere to the surface of the activated carbon. Although the physical adsorption strength is relatively weak, the large surface area of the activated carbon provides sufficient adsorption sites, showing good performance in removing mercury at low concentrations.

Chemical adsorption

Unlike physical adsorption, chemical adsorption involves a chemical reaction between functional groups on the surface of the activated carbon (such as oxidized groups) and mercury molecules, forming more stable mercury compounds. For example, oxides and chlorides can react with mercury to generate compounds that bind mercury and prevent its release. The intensity of chemical adsorption is higher, which can provide a longer-lasting effect on mercury removal at high concentrations.

Active Carbon Applications for Mercury Removal

Activated carbon, due to its excellent adsorption capacity and adjustable physicochemical properties, is widely used in mercury removal. Its main areas of application include the removal of mercury from flue gas and liquefied natural gas.

Mercury Removal from Flue Gases

In thermal power plants and other industrial combustion processes, mercury generally occurs in gaseous form in flue gases. Mercury contamination in these gases poses a threat to air quality and the environment.

Activated carbon, as an effective gas purification medium, can remove gaseous mercury through adsorption and chemical reactions, even under low temperature and high humidity conditions.

Since the mercury concentration is usually low, the high specific surface area and porous structure of activated carbon can provide abundant adsorption sites for mercury molecules. In addition, chemical groups on the surface of activated carbon can react with mercury, forming stable compounds that effectively remove mercury from flue gas.

Mercury removal from liquefied natural gas

Natural gas during the liquefaction process often contains traces of mercury, especially during the extraction, transportation and storage stages. Mercury not only causes corrosion in pipelines, equipment and liquefaction plants, but also affects the quality of liquefied natural gas. Therefore, mercury removal has become an important task in the liquefied natural gas industry.

Activated carbon has proven to be an effective material for mercury removal in liquefied natural gas production. By introducing activated carbon into the natural gas stream, mercury can be removed by physical adsorption and chemical reactions.

For low mercury concentrations, activated carbon can adsorb stably at low temperature, reducing equipment corrosion. In addition, by modifying the surface of the activated carbon, its selectivity and adsorption capacity towards mercury can be further improved.

Active Carbon Selection for Mercury Removal

Choosing the right activated carbon is key to ensuring effective mercury removal. Different types of activated carbon have different adsorption properties, so selecting the right activated carbon for specific applications can maximize its effectiveness. PuroCarbon offers the following types of activated carbon for mercury removal:

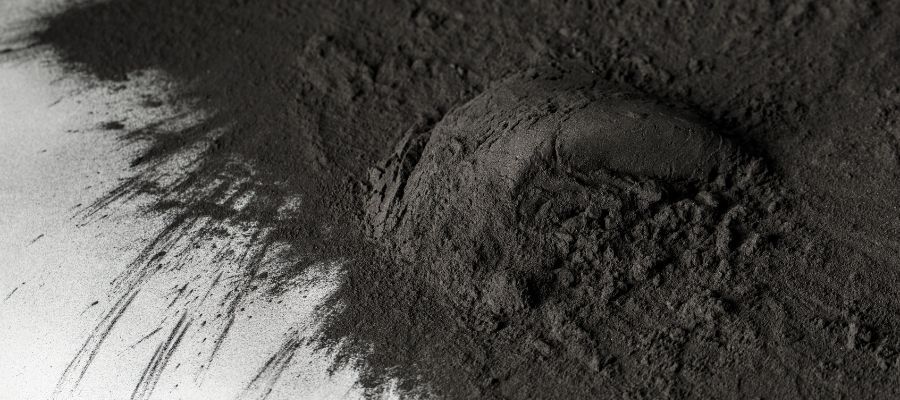

Powdered Activated Carbon

The powdered activated carbonDue to its excellent adsorption capacity, it is flexible in operation and easy to integrate into industrial flue gas treatment processes. It is widely used in the removal of mercury from flue gas.

Thanks to its small particle size, it has a large contact area with the flue gas, increasing the reaction rate and thus significantly improving mercury removal efficiency.

Impregnated activated carbon

For the elimination of mercury in liquefied natural gas, the following is used impregnated activated carbon with sulfur, which is an activated carbon treated with sulfur to improve its chemical adsorption capacity, especially suitable for the removal of mercury in liquefied natural gas.

This type of carbon reacts with mercury to form mercury sulfide, effectively fixing mercury in the pores of activated carbon, increasing the removal efficiency, and at the same time featuring high mercury capacity, low pressure drop and low dust, excelling in the field of mercury removal in liquefied natural gas.

Conclusion

Activated carbon, due to its exceptional adsorption properties, has become an important material in the removal of mercury in flue gas and liquefied natural gas. Through physical adsorption and chemical reactions, activated carbon can effectively remove mercury in these environments, ensuring environmental cleanliness and equipment safety.

If you are looking for an effective method for mercury removal, do not hesitate to contact us at. Our professional team will provide you with customized solutions for your purification process.

Frequently Asked Questions

Activated carbon adsorbs mercury through its highly developed porous structure. These pores provide a large surface area that allows the activated carbon to capture and retain the mercury molecules.

The activated carbon mercury removal process is intrinsically safe, but it must be performed correctly. Direct contact with activated carbon dust should be avoided and operation in a well-ventilated environment should be ensured to minimize the risk of dust inhalation.

The adsorption capacity of activated carbon decreases with time, so it is necessary to replace it periodically. Once the activated carbon reaches its adsorption capacity, it is no longer effective in removing mercury.