Activated carbon, as a charcoal material with a highly developed pore structure, plays an important role in various fields due to its powerful adsorption properties. A detailed description of activated carbon is given below:

Definition of Activated Carbon

Activated carbon is a porous carbon material obtained from materials with high carbon content (e.g. coal, wood, coconut shell, etc.) by a special process. Due to its complex internal pore structure, activated carbon has a huge specific surface area, which gives it a high adsorption capacity. It can effectively capture and remove pollutants and impurities in gases, liquids or dissolved solids and is widely used in various fields.

Activated Carbon Types

The types of activated carbon are not only differentiated according to the raw material, but can also be classified according to their shape.

Classification By Commodities

- Coconut shell activated carbonMade from selected coconut shells from Southeast Asia, it has a high strength and a microporous structure developed with low ash content, especially suitable for precious metal recovery, air purification and high-end water treatment.

- Carbon-based activated carbonmade of high quality anthracite or bituminous coal, with high adsorption capacity and cost-effectiveness, it is widely used in industrial wastewater treatment, gas purification and other fields.

- Wood activated carbonmade from wood or sawdust, with a large pore structure, it is suitable for pigment removal, odor control and food and beverage processing.

Classification By Shapes

- Granular activated carbonIt has high adsorption speed and good abrasion resistance, and is used in water treatment, air purification, medicine and chemical industry, etc. It has high adsorption speed and good abrasion resistance.

- Activated carbon pelletscolumnar or spherical activated carbon: also known as columnar or spherical activated carbon, it is commonly used in gas treatment and industrial waste gas cleaning, such as desulfurization and denitrification and solvent recovery, etc. It has good mechanical strength and low resistance.

- Powdered activated carbonvery fine particles, commonly used in liquid phase adsorption for decolorization and refining treatment, with excellent adsorption capacity due to their large surface area.

- Honeycomb activated carbonHoneycomb structure, commonly used in air pollution control and gas purification, widely used due to its low pressure drop and large specific surface area.

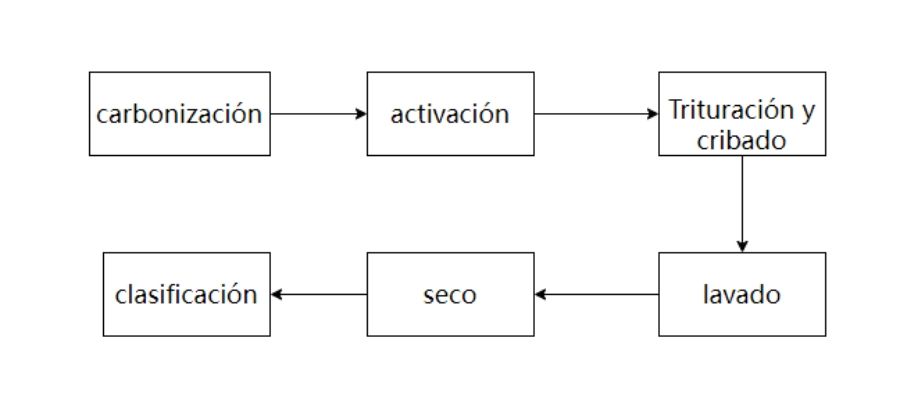

Activated Charcoal Manufacturing Method

The method of manufacturing activated carbon usually consists of two main steps: carbonization and activation. These two steps are described in detail below, along with other related processes:

Carbonization

Carbonization is the process of heating carbon-containing raw materials in an anaerobic or low-oxygen environment in order to remove volatile substances from the raw materials, such as moisture, oil and gas, etc., and at the same time form a preliminary carbonaceous structure.

- Preparation of raw materials: Select suitable raw materials to make activated carbon, common raw materials include wood, bamboo, coconut shells, etc. The raw materials are crushed and grinded to make the granularity uniform.

- Carbonization: The raw materials are fed into a closed carbonization furnace and carbonized at high temperature (usually 700-900℃). During this process, the organic matter in the raw material is gradually carbonized into solid charcoal.

- CoolingAfter carbonization, the carbonization furnace is shut down and the residual carbon is removed when the furnace temperature drops to room temperature for cooling. Cooling can be done with water or other liquids.

Activation

Activation is the process of developing the porous structure of the carbonized product, whereby the activated carbon acquires a high specific surface area and a large number of micropores, thus improving its adsorption capacity.

- Physical activationAfter carbonization, the solid carbon is placed in a special reaction vessel and physically activated at high temperature and pressure. The most commonly used activators are water vapor, CO2, etc. The activator passes through the activation vessel at a given flow rate and reacts with the carbon to increase its surface area.

- Chemical activationChemical activation: carbon is chemically reacted by adding certain chemicals (e.g. alkaline compounds) to increase its activity. Chemical activation is often used to prepare highly active activated carbon.

Crushing and Screening

After activation, activated carbon usually has to be crushed and sieved into different particle sizes to meet the needs of different applications.

Washing

To remove residual chemicals and impurities, the activated carbon must be washed with water and sometimes treated with an acid or alkaline solution.

Dry

After washing, the activated carbon must be dried to remove moisture, a step that is usually done with hot air.

Ranking

Dry activated carbon is graded according to particle size, shape, density and other characteristics to ensure that the product meets specific specifications.

Request a QuoteActivated Carbon Adsorption Principle

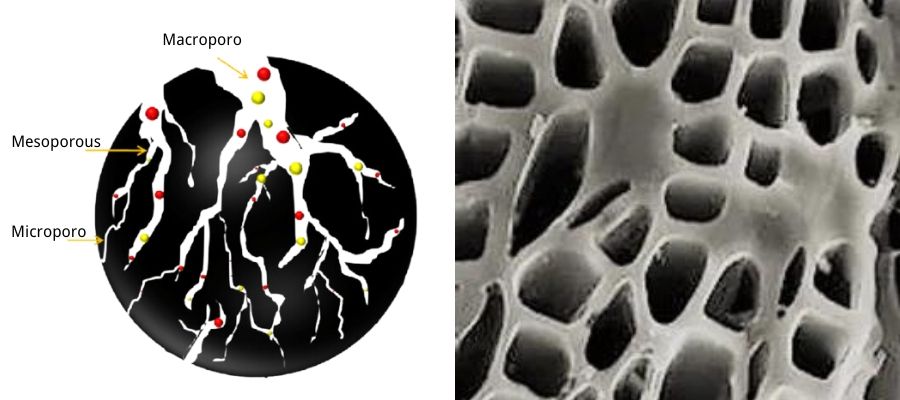

Activated carbon is a material with high adsorption properties, mainly used for adsorption of organic substances in water and air. Its adsorption principle mainly involves physical adsorption and chemical adsorption.

Physical adsorption

Adsorption on activated carbon is based on the principle of physical adsorption. Physical adsorption is achieved by intermolecular adsorption by Van der Waals forces or charge interaction forces. Activated carbon has a highly developed pore structure with a wide pore size distribution and a large pore volume.

This gives the activated carbon a large number of micropores and mesopores and a large specific surface area. This structural feature provides good conditions for physical adsorption. Organic matter molecules enter the pores by diffusion and, due to the presence of adsorption forces on the pore surface, the molecules are captured and remain on the pore walls.

Chemical adsorption

Activated carbon adsorption also involves chemisorption. Chemisorption is the adsorption of organic substances by chemical reaction with the adsorbent through chemical or ionic bonds.

Activated carbon is rich in reactive functional groups, such as hydroxyl, ketone, aldehyde and carboxyl groups. These functional groups can interact with the reactive groups contained in the organic substances in the form of chemical bonds and adsorb the organic substances through chemical reactions.

Request a QuoteCustomized Active Carbon

We offer impregnated activated carbon and acid-washed activated carbon for specific industrial applications, where the adsorption properties of the activated carbon are enhanced or altered by special treatments to meet specific application requirements.

Impregnated Activated Carbon

The impregnated activated carbon is manufactured by mixing activated carbon with specific chemicals to enhance its ability to adsorb certain specific pollutants. This treatment is effective in removing harmful gases such as hydrogen sulfide, sulfur dioxide, ammonia and other acid gases.

The choice of impregnation agent depends on the target contaminant, and common impregnation agents include chemicals such as potassium permanganate, silver, copper oxide, or substances such as zeolites and activated alumina. The impregnation process involves bringing the activated carbon into contact with an impregnating solution, followed by a drying and activation process to ensure that the impregnant is evenly distributed throughout the pore structure of the activated carbon.

Request a QuoteActivated Carbon For Acid Washing

The acid-washed activated carbon is a type of activated carbon that has undergone an acid chemical treatment designed to improve its adsorption properties and decontamination capacity.

By removing surface impurities with dilute acid, the specific surface area and porosity of acid-washed activated carbon are improved, while adding functional groups to enhance the selective adsorption of organic pollutants and heavy metal ions. It is widely used in the fields of water treatment, air purification and medicine, becoming an important material for effective pollutant removal.

Purocarbon offers a wide range of types of impregnated and pickled activated carbon to meet your various needs.

Request a QuoteActivated Charcoal Application

Activated carbon has a wide range of applications in various fields due to its powerful adsorption properties and extensive porous structure. Some of the main applications of activated carbon are listed below:

Water Treatment

- Drinking water purificationremoves chlorine, organic contaminants, odors and colors from tap water to improve its quality.

- Industrial water treatmentRemoves impurities and contaminants, such as heavy metals and organics, from water during industrial production.

Air Purification

- Indoor air purificationin air purifiers for homes and offices to remove harmful gases, odors, viruses and bacteria from the air.

- Industrial exhaust gas treatmentin chemical and pharmaceutical industries to remove organic pollutants and noxious gases from exhaust gases.

Gold Refining

Activated carbon is used to adsorb gold particles in the gold processing process. gold refining to achieve its separation and purification. The high surface area and porous structure of activated carbon allow it to adsorb large amounts of gold, which is then extracted from the activated carbon by a specific treatment method.

Request a QuoteFood Industry

- Bleaching and refiningis used in the production process of sugar, oils and fats, alcohol and other products to decolorize and improve product quality.

- eliminate odorsto remove pigments, odors and impurities from beverages and foodstuffs.

Pharmaceutical Industry

- Drug bleaching and purificationis used in the production of pharmaceuticals to remove impurities and colorants from pharmaceuticals.

- Blood purificationis used in certain sanitary products to eliminate toxins and impurities from the blood.

Chemical Industry

- Catalyst carrierIn chemical reaction, it is used as a catalyst carrier to improve the reaction efficiency.

- Solvent recoveryin the chemical production process, it recovers organic solvents, reducing environmental pollution and cost.

Agriculture

- Soil improvementImproves soil structure, increases soil permeability and water retention.

- Fish farmingin aquariums, for filtration and purification of water

Our company is always developing new products and applications, if you have other applications, please feel free to contact our professional team and we will provide you with customized solutions.

Request a QuoteHow to Buy Activated Carbon

PUROCARBON se dedica a la industria del carbón activado desde hace más de 18 años y ha acumulado una rica experiencia en el sector. Y contamos con un equipo técnico profesional para ofrecer soluciones personalizadas según las necesidades específicas de los clientes. Si desea comprar carbón activado o buscar asistencia técnica, no dude en ponerse en contact with us, le proporcionaremos productos de alta calidad y un servicio atento.